Iron Working at L’anse aux Meadows

One of the conspicuous aspects of the L'Anse aux Meadows site was the archaeological discovery of iron working there.. By the time the Norse came to L’Anse aux Meadows, iron had been made in Scandinavia for close to 1500 years. During all that time and until a couple of centuries after L’Anse aux Meadows was abandoned, the raw material for iron was iron found in lakes and bogs. In northerly regions such as L’Anse aux Meadows and much of Scandinavia, many lakes and bogs have iron dissolved in their water. They also contain certain acids which form a chemical reaction with the iron, making it form into small lumps or crusty slivers. When such lumps and slivers, the ores, are heated to very high temperatures, they melt into a solid lump of iron, a bloom. This lump can then be hammered and forged into iron objects.

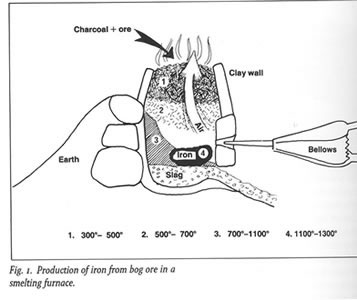

The ore contains not only iron but other less desirable materials such as sand, manganese and aluminium. These materials melt at a lower temperature than the iron. This makes it possible to drain them away from the iron. As they cool off, they become solid and form slag.

The smelting of the iron took place in a furnace. In the Viking Period most furnaces were small simple structures of clay and stone, no more than about 60 cm high and 30-40 cm in diameter. The ore was packed in layers into the furnace, with charcoal between each layer. Charcoal was used instead of wood because it burns at a higher temperature than plain wood. For the iron to smelt, a temperature of at least 1100° Celsius was needed. However, in order to reach this temperature, one also had to pump air into the furnace with bellows. The bellows had a metal snout, a tuyière, which was inserted through a hole into the furnace. It was operated by hand at strategic intervals determined by long experience, a task that requires considerable strength and perseverance.

The ore was wet when it was collected. Before being packed into the furnace it was generally roasted. The wet ore was placed on a bed of wood. The wood was lit, and when the fire was out, much of the water trapped in the ore had evaporated. The firing also removed some of the sulphur often present in bog ore. Too much sulphur makes the iron impossible to work.

The first iron in North America was probably made at L’Anse aux Meadows but what did the Vikings need it for?

Books

Chapters in Books

Maps